The use of 3D printing within the medical sector has become a very valuable ally for hospitals

From start to finish. With all the possibilities of materials and technologies. With all the medical certificates. In record time. With the full support of the bioengineers. This is the 3-D printing service provided by the AVINENT Digital Health line to the medical centres and hospitals that have decided to opt for additive manufacturing processes, but do not want 3D printing to cause them headaches. As easy as that.

The use of 3-D printing within the medical sector has become a very valuable ally for hospitals. At this present time, AVINENT, with its commitment to offering a comprehensive service with a wide range of possibilities, is the company that is most encouraging healthcare centres to join the 3D printing revolution without fear. The company has become the best supplier of customised medical solutions thanks to a variety of factors.

Firstly, the company has proven experience in the medical sector, as it has dedicated more than 10 years to working with 3D printing in the dental sector and it has a high level of knowledge of biotechnology and the manufacture of customised products using 3D printing.

Secondly, AVINENT offers a vast range of possibilities in respect of materials and manufacturing methods. The company’s facilities boast a wide range of additive manufacturing technologies, using different materials and methods. This is in addition to the global, pioneering digital equipment, which allows it to offer healthcare professionals a wide range of possibilities to address and resolve any situation. It should be noted that among the different families of additive manufacturing technologies, AVINENT has equipment that functions with the most advanced technologies and which allows all types of projects to be undertaken without exception: we have Material Jetting, SLA, DLP, CDLP, MultiJet, SLS, DMLS and SML technologies.

With regard to materials, AVINENT is aware of how important it is for hospitals to have a product and service that offers a wide variety of components of which some are suitable for sterilisation. It is with this in mind that it offers optimal, biocompatible and sterilisable materials, such as resins, synthetic polymers, titanium and cobalt chromium.

Through the use of 3D printing, the AVINENT Digital Health line produces models of organs that can be used to simulate surgery, thus reducing intervention times and providing additional peace of mind to the patient and the professional; surgical guidelines, which facilitate the surgeon’s work and have infinite possibilities; and lastly, it also produces Patient Specific Implants, pieces which are designed and manufactured to be implanted inside the human body. As a new development, and within the segment for models used for simulating surgeries, the company today has equipment capable of generating models of organs that are hyperreal, with different textures and colours. This is a service of great value for those medical professionals who need models that are extraordinarily detailed.

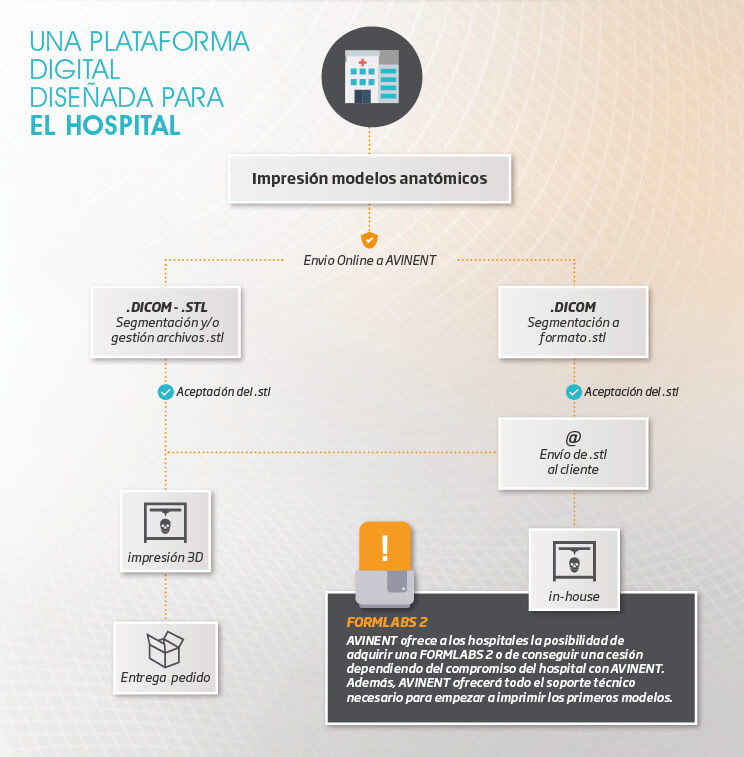

AVINENT provides a complete digital flow service, beginning with the receipt of the files in .STL and .DICOM format sent by the health care centres, followed by their subsequent segmentation and management, and then waits for the hospital to approve the proposal for the model. Once received, a final report is submitted with all the specifications of the patient, the 3D printing is carried out and the order is delivered within a maximum of 48 hours.

Furthermore, thanks to its partnership with the company Formlabs, AVINENT also offers hospitals and healthcare centres the opportunity to have a Formlabs2 printer at their facilities, together with all the necessary technical support, in order to take their first steps into the complex world of 3D printing.

The whole process is compliant with demanding healthcare regulations that affect the facilities, processes and products. Accordingly, the communication and service platform have the necessary certificates that endorse the commitment of the company with the professional, and ultimately, with the patient.