There are many ways in dentistry to restore teeth with implant-supported prostheses. New generation materials combined with an optimal implant system provide considerable benefits.

One of the goals that all professionals want is to ensure the success of an implant treatment, but if you consider all the variables that can affect this it is obvious that there is no one definitive solution. Nonetheless, the sector should take full advantage of experience, research and technology to apply a treatment that is as efficient as possible.

This is why there are solutions that are backed by clinical studies and in vitro tests supporting many of the theories arguing that a restoration can be a guaranteed success.

This is the case of VITA ENAMIC implant-supported restorations on AVINENT implants. This solution combines simplicity and speed of implementation with some ideal technical characteristics, so that when they are applied together in specific cases the results are always satisfactory.

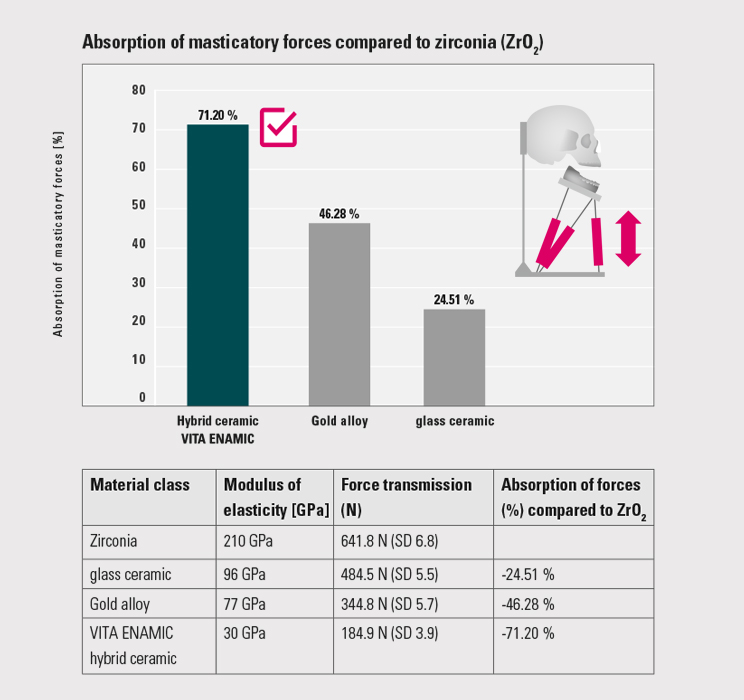

VITA ENAMIC is a new generation CAD-CAM material formed by a hybrid dental ceramic with a dual-network structure. This provides it with a number of competitive benefits, one of which is its huge load-bearing capacity, as demonstrated by the results of the following in vitro tests:[1]

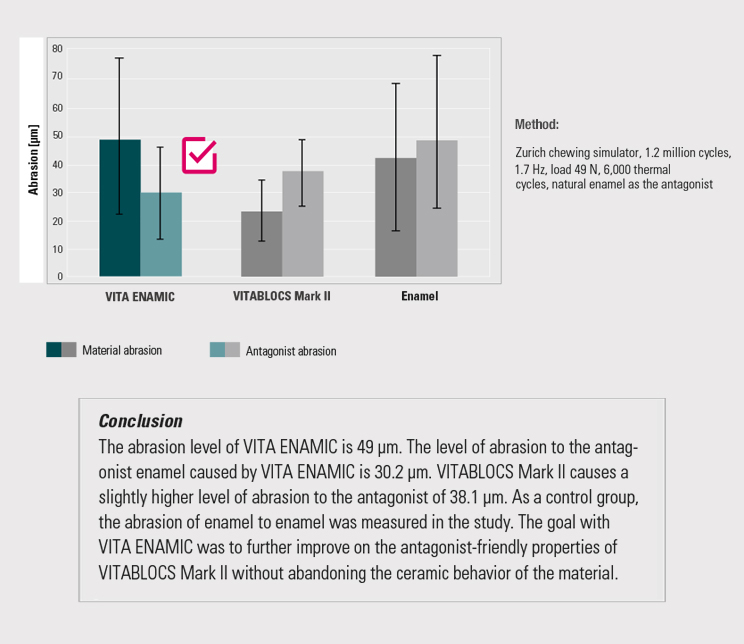

The VITA ENAMIC material can therefore be described as very resistant and with a modulus of elasticity of 30 GPa, thereby helping to absorb masticatory forces of up to 70%, well above other materials available on the market. This also means that the abrasion of the antagonist is much lower than in other ceramics, so that the enamel remains in better condition compared to the already well-known VITABLOCS Mark II.

But how are these benefits transmitted in implant-supported prostheses? The VITA ENAMIC on AVINENT implants solution has one important component: titanium bases,[2] a product that, like the material, must be tested to ensure excellent load-bearing capacity. Moreover, AVINENT’s titanium bases are available in various gingival height designs, so professionals can choose the most suitable in each case to preserve soft tissue and obtain optimal emergence profiles. In addition, its digitization means that they can be used with VITA ENAMIC in a fully digital process using digital software and in most market bookstores.

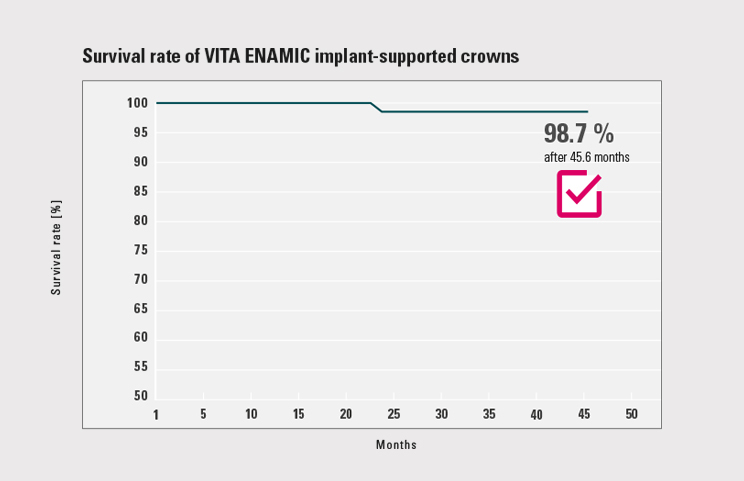

Once the independent qualities of VITA ENAMIC and the titanium base have been analyzed, the excellent behavior of the whole on the implant must be ensured. Therefore, the survival rate of this solution is measured. We can see the results of the study in the chart below, which shows that the solution has sufficient relevant objective data to be established as a reliable, long-term option when compared with the results of the static breaking load in implant-supported crowns[3] (approx. 926N).

All this data has a common end goal, which is to create an efficient solution for the patient. So if the VITA-AVINENT solution as a whole presents the aforementioned technical qualities and characteristics, to which we can add its easy makeup process, esthetic benefits and optimal CAD-CAM design, we are presented with a perfect, versatile solution to be used in implant-supported restorations.

What follows is a clinical case of an implant-supported crown using digital workflow with VITA ENAMIC restorations on AVINENT implants. A clear example that shows the direct impact of the use of quality products on the success of implant treatments.

[1] Menini, M. In vitro test on the shock absorption capacity of VITA ENAMIC hybrid ceramics. Department of Fixed Dental and Implant-supported Prostheses, University of Genoa (Italy), 2015.

[2] Internal analysis, AVINENT R&D Dept. Product tested according to ISO 14801 standard. BIO20130812 report.

[3] Internal analysis, VITA R&D Dept.: VITA Zahnfabrik, H. Rauter GmbH & Co. KG, Inorganic Chemistry Research & Development Department, Spitalgasse 3, 79713 Bad Säckingen. Michael Gödiker, Head of Inorganic Chemistry in the R&D Dept., Bad Säckingen, Dr. Jens Fischer, Professor, Director of Inorganic Chemistry in the R&D Dept., Bad Säckingen. Version: 07.13.