The use of new and innovative materials, combined with CAD/CAM technology, enables us to expand the possibilities for therapeutic treatments and to obtain far more precise, esthetic and satisfactory results.

INTRODUCTION

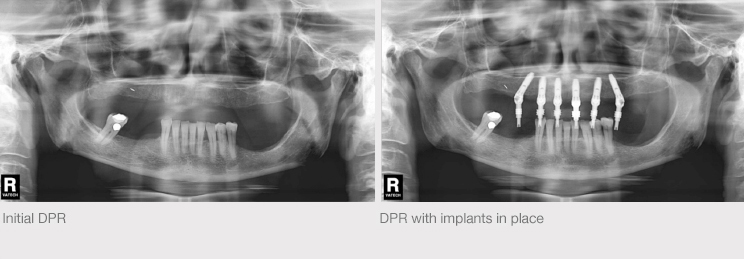

Seventy-five-year-old patient with a removable partial prosthesis in her upper jaw, no relevant disease. She came to the clinic looking for a fixed solution to restore her teeth.

Due to the patient’s bone resorption and maxillary sinus pneumatization, immediate loading surgery was carried out in 2013, angling the back implants to avoid the bilateral sinus lift.

Following the period of osseointegration, a hybrid acrylic prosthesis was screwed in place. During the subsequent regular check-ups, an accumulation of bacterial plaque on the prosthesis and bone resorption in the back implants were observed.

Three-monthly follow-ups were done for a period of three years, during which professional hygiene treatments on the implants and prosthesis were performed, slowing down the resorption but without alleviating the problem of plaque retention.

THE ALTERNATIVE TREATMENT

The research and development of new and innovative alternative materials to metal alloys, such as high-performance polymers, paves the way for a wide range of therapeutic possibilities in implantology and implant-supported prostheses for treating this type of case.

A thermoplastic known as PEEK (polyether ether ketone) has been used for many years in orthopedics and traumatology due to its properties and behavior. It is an elastic, light-weight, non-metal, biocompatible solution that offers outstanding mechanical resistance to corrosion, making it ideal for fabricating structures, accessories and fixed and removable prostheses.

For all these reasons, the decision was made to try an alternative treatment in this case by making a screw-retained PEEK and composite hybrid prosthesis.

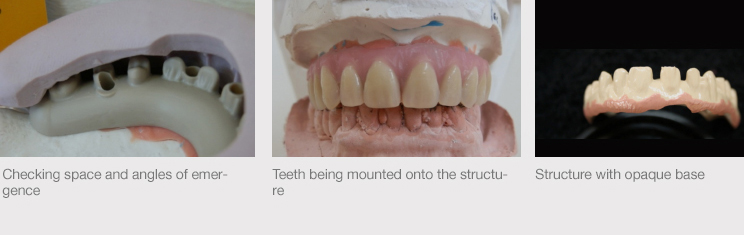

The impression was taken and a master model was made in the laboratory with analogs for transepithelial abutment. A screwed articulation plate to improve stability during testing in the mouth was made to enable the direction of the implants to be observed at the moment of placement. The teeth were placed in keeping with the desired final result in order to evaluate the articulation, color and shape of the teeth, the esthetic of the placement, etc. This assembly was screwed to six metal chimneys to assess whether angling was required.

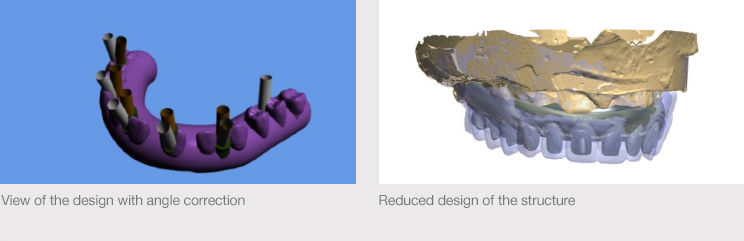

The study was sent to the AVINENT-Core3dcentres milling center for digitizing and the STL file obtained was used to design the final PEEK prosthetic structure screwed to the six implants.

In this case, and in accordance with the recommendations of the laboratory, the angle at which the screws emerged from the structure was corrected, as the axis of some of the implants meant that they pointed outwards slightly due to the patient’s residual bone.

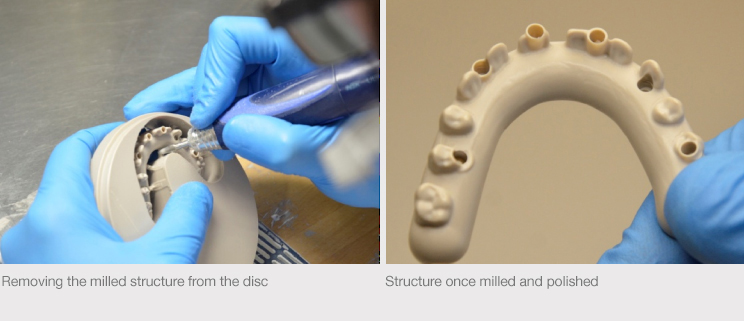

Once the final design of the restoration had been approved by the clinic, the structure was milled from a PEEK disc (Juvora Dental Disc, Juvora Ltd., UK). Milling is a fabrication process that guarantees a perfect fit and no subsequent manual retouching of the structure is required. It was sent back to the clinic once again for testing in the mouth.

Once the case had been validated, the standard protocol of the manufacturer of the material was followed.

The restoration was placed and the patient was given an appointment for a three-monthly check-up to see how it was progressing. At this first check-up, it was found that there was minimal plaque retention and the mucosa around the implants had a healthy appearance. A program of six-monthly check-ups was arranged.

CONCLUSION

The use of new and innovative materials, combined with CAD/CAM technology, enables us to expand the possibilities for therapeutic treatments and to obtain far more precise, esthetic and satisfactory results.

The excellent properties of PEEK and its tried-and-tested use in the field of medicine make it a good alternative in dentistry, an ideal option for making structures, accessories and fixed and removable prostheses.