These partnerships make it possible for AVINENT to currently offer a range of products with high added value that are increasingly sophisticated. In recent years, the company has helped more and more laboratories and clinics to use the most advanced CAD-CAM technology, latest-generation scanners, planning software and 3D printing systems, new materials, milling machines and more. This dynamic is one of the foundations of AVINENT’s success, as the company remains open to new products that improve the customer’s experience during all stages of the digital flow.

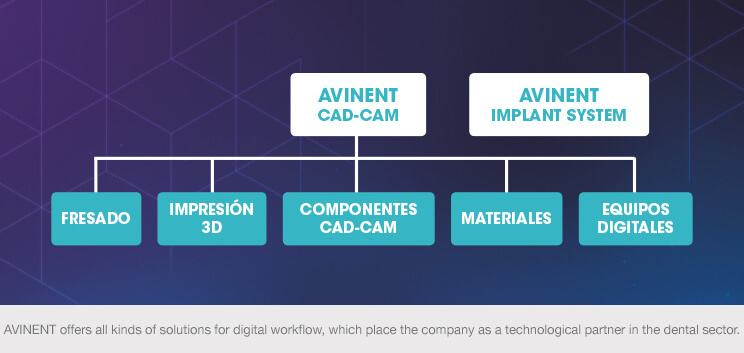

If we study in detail the value proposition that AVINENT has been developing continuously to expand its CAD-CAM solutions, we see that it has currently covered all or most of the market demand.

Milling is one of its main product ranges, but new digital components are constantly being developed. The materials are another key element for choosing specific restorations and as technological partners we must always provide the most advanced solutions. Likewise, we work intensely to transfer the latest developments in digital equipment to all interested parties (laboratory scanners, milling machines, 3D printers) by providing the most efficient CAD-CAM software and the most advanced 3D printing solutions.

Thus, AVINENT stands as the technological partner par excellence of the dental sector, offering laboratories and clinics all its knowledge accumulated through scientific research and countless tools and technologies.

Recent technological developments have caused a paradigm shift in the dental sector from which there is no turning back. In fact, digital environments and the customization of products and solutions will be increasingly important in the field of medical technologies. This transformation gives patients many advantages, since products are designed and made based on their individual needs. Therefore, the customization of dental prostheses with CAD-CAM technology is no longer just the future of dentistry, but is now supplemented by new and much more advanced production technologies.

According to this concept, AVINENT will soon present a new range of customized products using 3D printing as the main method of production. In this new system to produce and design complete or anatomical structures, we will find solutions for the now well-known cobalt-chrome (CoCr) and titanium.

One of the products available earliest will be LUNAR anatomical crowns, which are 3D printed in CoCr with unbeatable finishes available on the natural tooth. In addition, complete titanium AURORA structures, a totally groundbreaking concept, represent the titanium 3D printing revolution applied to the dental prosthesis and esthetic solution sector.

These structures have a mesh-like texture to keep the product light and to improve retention of the resin. Their most important features include the machining of the connection and placement of the screw, their lightness due to the method of production, their reduced rigidity compared to conventional structures, their greater retention of coating materials and their high biocompatibility, which mean more comfort for the patient.

This product is unprecedented in the field of CAD-CAM prosthetic restorations. It was developed by the R&D Department with the latest titanium 3D printing technologies and advanced software and with the collaboration of top companies in the dental sector.

Titanium is exceptionally resistant – the most resistant material available for 3D printing. Its unique properties of biocompatibility make it the material par excellence for use in medical prostheses. AVINENT CAD-CAM has developed this innovative structure to improve and expand the range of prosthetic solutions available in the market and to provide an unprecedented new option positioned between traditional hybrids and metal-ceramic restorations.

AURORA structures represent a true revolution in CAD-CAM prostheses as we know them, greatly expanding possibilities for clinics and laboratories to develop new treatments and creating new horizons in a market that is constantly evolving.