Wearing a prosthesis that is truly incorporated into the body, one that not only disintegrates over time, but also naturally promotes the regeneration of the patient’s real bone, is no longer science fiction. AVINENT and the Institut de Bioenginyeria de Catalunya (Institute for Bioengineering of Catalonia, IBEC) are jointly developing an ambitious project to create 3D printed pieces from biomaterials.

These prostheses will represent an enormous leap in the patient’s quality of life, given that they will greatly improve the characteristics of a classic prosthesis. As AVINENT R&D Manager Anna Cortina points out: “The fact that the patient can wear a piece that degrades and does not have to think about a second operation or future complications is a major leap forward.” Cortina explains that sometimes “titanium prostheses, for example, cause the surrounding bone not to regenerate as optimally. This will not happen with 3D printed parts made from bioactive nanoparticles.”

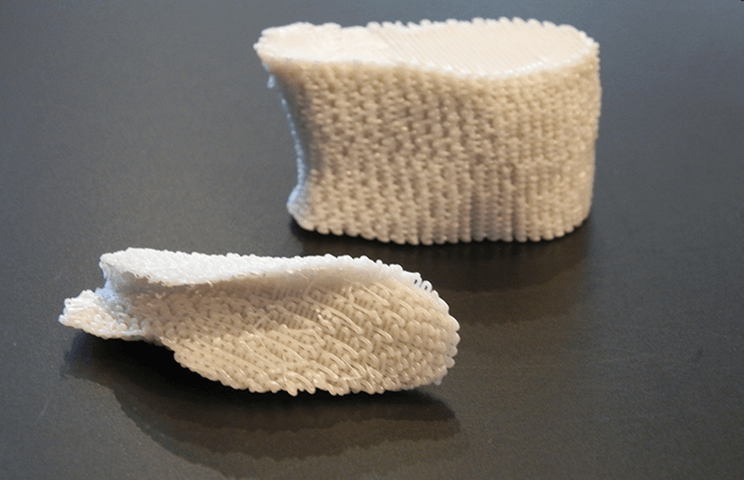

On the one hand, the AVINENT company has proven experience in designing and creating customized solutions for the medical dental sector using digital technology, and on the other, IBEC has a long history in the manufacture of materials for repairing and regenerating bone tissue. By joining together their know-how, the two organizations have first managed to digitally reconstruct the defect or bone fracture and then to select the most suitable biomaterial to print the prosthesis. These biomaterials comprise polymers and nanoparticles that are provided with the necessary porosity through 3D printing for the patient’s cells to circulate and colonize the area by promoting the regeneration of damaged tissue. This means that the prostheses are made of a material that not only gradually disappears, but also promotes the regeneration of the patient’s bone tissue. Bioactive nanoparticles act as an attraction point, calling on cells to migrate to the affected area and repopulate it. The prosthesis becomes the patient’s own bone after three years, with its blood vessels and sensitivity. Real bone. Dr. Elisabeth Engel, director of IBEC’s Biomaterials for Regenerative Therapies group, explains: “This solution represents a complete paradigm shift as regards the use of metallic prostheses, which do not promote tissue regeneration, but rather permanently replace the damaged area.”

AVINENT and IBEC have so far demonstrated the success of bioprinted pieces on a chicken embryo membrane, a fertilized egg membrane; the next step is to see how they respond in mice. The plan is then to test them on animals more similar to humans. The first decisive step towards the creation of personalized bioactive products will be applied in the cranio-maxillofacial field, but given the scalability of 3D printed biomaterial production, the partnership between both organizations aims to expand its field of application, developing and manufacturing solutions for other parts of the human body.

With this 3D bioprinter, one of the few offering the level of precision and features needed in regenerative medicine in southern Europe, IBEC and AVINENT are at the forefront of a new technological revolution that will represent a paradigm shift and clear improvement in the quality of life of patients.

More information here.