Virtual design and planning systems for orthognathic surgery help to enhance the accuracy and safety of the procedure and reduce surgical times.

We can differentiate between traditional and customized solutions among the solutions that can be found within these surgeries. The main difference lies in the case planning process and virtual design of the osteotomy and plates to be implanted into the patient.

Although AVINENT has both options available, there are several interesting features that should be highlighted when differentiating the two processes.

Serialized plates vs customized plates

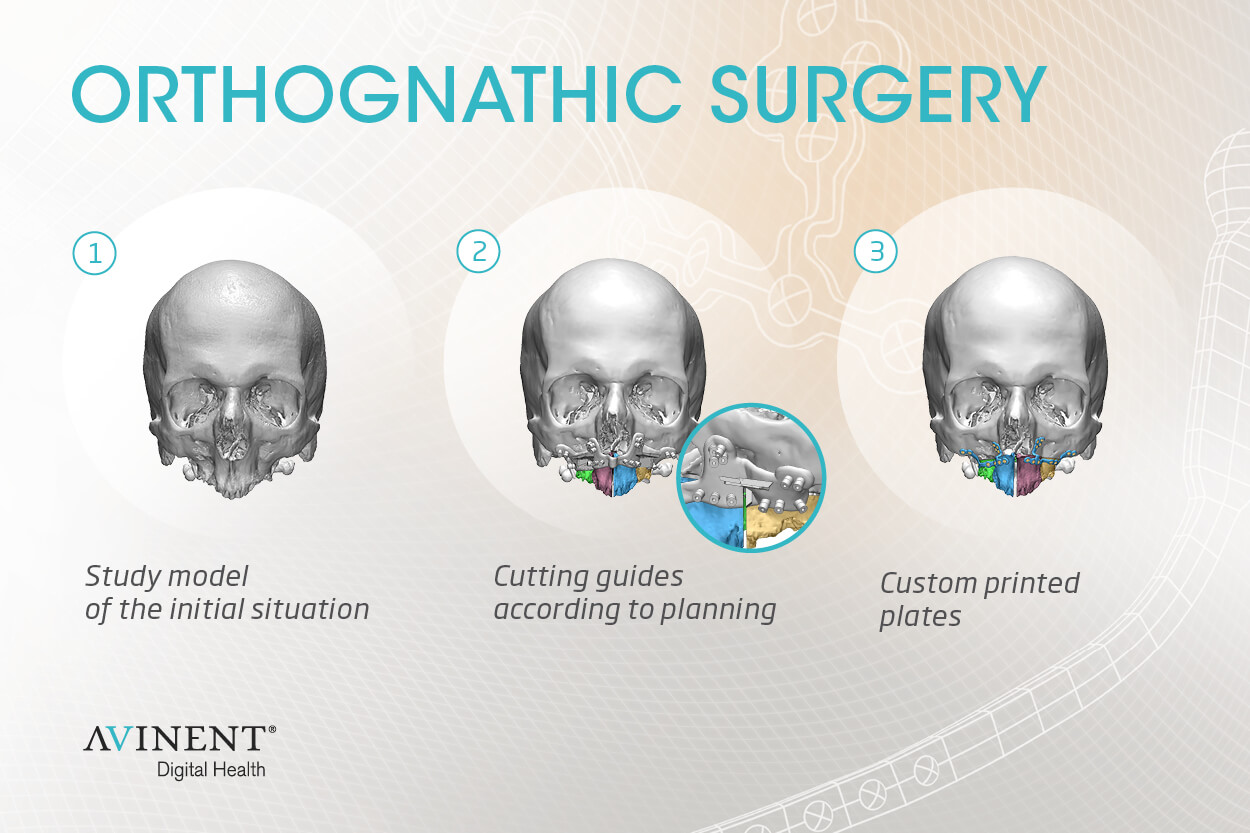

Technological advances in planning and 3D printing have enabled the production of customized medical devices using a complete digital workflow. Virtual design and planning systems for orthognathic surgery help to enhance the accuracy and safety of the procedure and reduce surgical times.

Listed below in this first article are three basic features that define customized plates:

1. Cutting guides

Cutting guides help us to commence our osteotomy exactly as we have digitally designed it and they also indicate to us the location of the screw holes in which our customized titanium plates will be positioned after the programmed feed rate, thereby achieving more accuracy and reducing surgery times.

2. Titanium plates

Customized titanium plates already in the shape of our feed rate help us to carry the maxillae or mandible to the exact previously designed position, thereby also reducing the time in preparing a serialized plate (bending, positioning, etc.) and achieving more reliable results.

3. Mentoplasty

By using the pre-designed cutting guides and perforations, we can spatially position the chin fragment by screwing it into the exact position that we have virtually planned. This provides us with more accuracy and reliability during surgery.

A reliable process

Avinent Digital Health helps us to perform all these processes thanks to a virtual design system that uses specially designed software for this purpose. The design and planning process is carried out in permanent connection with the professional so that the surgeon can understand the bone structure to be operated on before commencing with the patient. This guarantees optimum reliability when intervening, as it allows the printing of prior anatomical study models that help to plan the surgery and control how it will be performed.

The most advanced orthognathic surgery requires exhaustive planning in which any possible contingencies that may occur can be taken into account. In this way, bone contacts can be detected and osteosynthesis screws can be positioned in safe areas of good bone quality.

The use of digital technology in the planning of orthognathic surgery cases therefore helps to preview surgeries with high levels of detail and extremely precise control of the entire process. This type of guided surgery offered by Avinent Digital Health greatly increases the acceptance of the implanted product and reduces recovery times, as well as providing esthetic appearance recovery and improving the quality of life of patients.